1

/

of

1

Sanzhu Machines

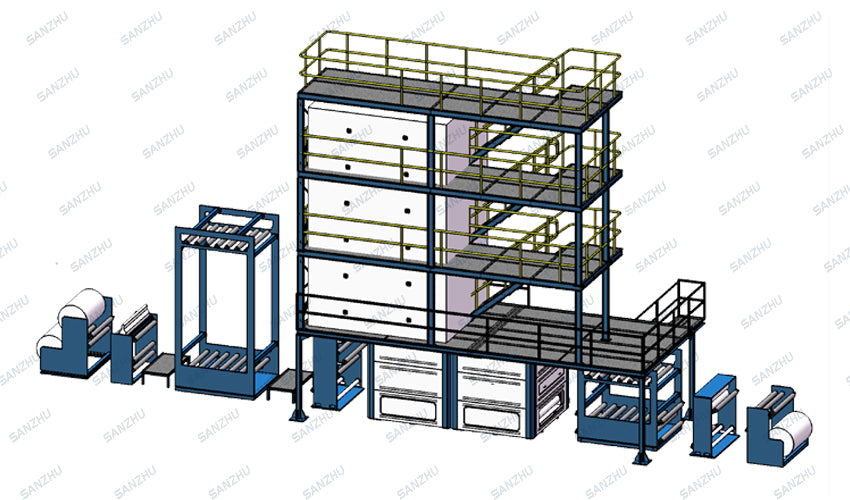

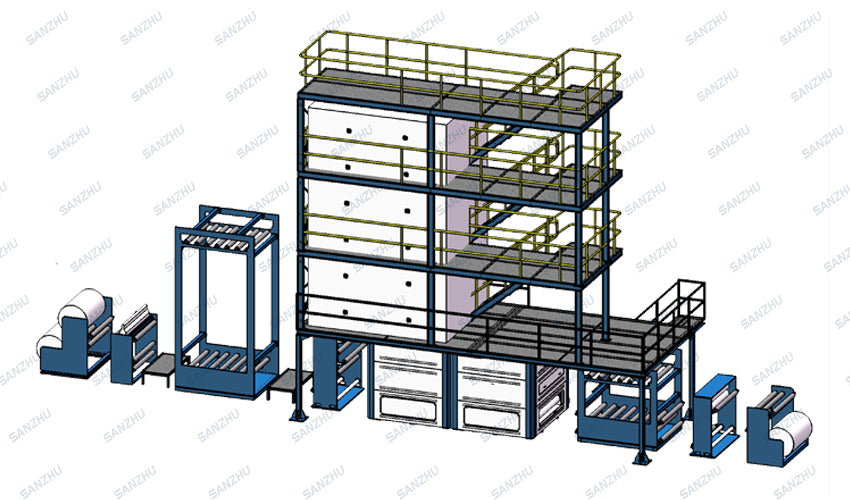

Fiber Fabric Impregnation Production Line

Fiber Fabric Impregnation Production Line

Description:

The radiant oven process allows the entire coating volume to be heated simultaneously. The frequency range of infrared heat waves allows efficient absorption by the resin. When using a conventional dryer system, the temperature distribution across the thickness of the web becomes almost constant, instead of being maximum at both surfaces and minimum at the center of the thickness. This heats the material faster, evaporates the solvent faster, and cures the resin faster without other undesirable effects such as overheating or skinning (bubbles).

- Process: Prepreg solvent-based

- Type: Vertical/horizontal processor (impregnation line)

- Machine principle: Fibers are impregnated by impregnation (a mixture of resin and solvent), with the goal of complete saturation. The fibers are graded and the solvent is evaporated using a radiant oven.

- Working width: 1200-1800 mm

- Production speed: 1-30m/min.

- Resin type: epoxy, phenol, polyamide

- Solvent type: acetone, MEK, toluene, etc.

Advantage:

- Prepreg contains almost no air.

- Consistent cure from core to surface.

- Short curing time and high product quality.

- Maximum energy efficiency.

- Instant temperature regulation.

- Strict personal partition control.

Share